A blog for students, families, and fellow educators. Meaningful reflections, stories, ideas, advice, resources, and homework help for middle school, high school, and college undergraduate students. We're exploring history, philosophy, critical thinking, math, science, the trades, business, careers, entrepreneurship, college majors, financial literacy, the arts, the social sciences, test prep, baseball, the Catholic faith, and a whole lot more. Join the conversation.

Pages

- Home

- About Aaron and this blog

- Aaron's teaching philosophy

- Aaron's Resume / CV

- Tutor in Sioux Falls

- Adult tutor in Sioux Falls

- Catholic Speaker in Sioux Falls

- Noteworthy interviews by Aaron

- Connect with Aaron

- Aaron - Testimonials

- Mental health resources for students

- Support Mr. Robertson’s Corner

- For homeschool parents

- For AP students and AP teachers

- For adult learners

- Free worksheets, learning games, and other educational resources

Search Mr. Robertson's Corner blog

Search Wikipedia

Thursday, May 1, 2025

Edsel Ford

Early life and family legacy

Edsel Bryant Ford was born on November 6, 1893, in Detroit, Michigan, the only child of Henry Ford, founder of the Ford Motor Company, and Clara Bryant Ford. As the sole heir to one of the most influential industrial empires in American history, Edsel was born into privilege but also immense pressure. His father was a mechanical genius and a domineering figure whose vision reshaped transportation and American manufacturing. Edsel, by contrast, was more refined, thoughtful, and artistic - qualities that often set him at odds with his father’s stark utilitarianism.

Edsel attended the Detroit University School, a private preparatory academy, and from an early age showed an interest in design and aesthetics, often sketching automobiles and demonstrating an appreciation for the visual aspects of car production. Though he was groomed to succeed his father at Ford Motor Company, his path was not entirely smooth. The elder Ford’s relentless drive and resistance to change often clashed with Edsel’s more progressive outlook.

Rise in the Ford Motor Company

Edsel officially joined the Ford Motor Company as a young man and quickly took on more responsibility. By 1919, at just 26 years old, he was named president of the company when Henry Ford temporarily stepped back to focus on other interests (although in practice, the elder Ford still held much of the decision-making power).

Edsel’s presidency marked a quiet but significant shift in Ford’s trajectory. He was instrumental in steering the company toward modernization in both design and business practices. He supported the diversification of the product line, pushing the company beyond the utilitarian Model T, which his father stubbornly clung to long after the market demanded change.

The purchase of Lincoln Motor Company

One of Edsel’s most important business decisions was the acquisition of the Lincoln Motor Company in 1922. Founded by Henry Leland - who also co-founded Cadillac - Lincoln was struggling financially in the post-WWI market. Edsel saw its potential, not just as a brand but as a platform to build a luxury vehicle that Ford lacked. While Henry Ford viewed cars primarily as functional tools for the masses, Edsel envisioned automobiles as both utility and art.

Under Edsel’s leadership, Lincoln became Ford’s luxury marque. He used the brand to experiment with styling, coachbuilding, and premium engineering. He hired prominent designers, such as Raymond Loewy and E.T. Gregorie, and supported advanced design studios long before they became industry standard. The results elevated Lincoln’s reputation and laid the foundation for Ford’s design-centric future.

Design sensibility and creative vision

Edsel had a keen eye for beauty in machinery, which showed in every project he touched. He championed elegant, streamlined design during an era when many cars were still boxy and utilitarian. His vision culminated in vehicles like the Lincoln Zephyr (1936) and the original Lincoln Continental (1940). The Continental, in particular, is considered one of the most beautiful American cars ever built. Frank Lloyd Wright even called it “the most beautiful car ever made.”

Edsel worked with designers like Bob Gregorie to develop cars with cleaner lines, lower profiles, and an air of sophistication. These vehicles contrasted sharply with the blunt, functional style his father preferred. Edsel also supported modern advertising and branding efforts, introducing a more refined and aspirational image to Ford’s messaging.

Business philosophy

Edsel Ford believed in balance - between function and form, mass production and customization, tradition and innovation. He respected the foundation his father built but saw the need for evolution. Unlike Henry, who prioritized low cost and simple production, Edsel was more interested in product diversity, quality, and visual appeal. He understood that consumers wanted not just transportation but expression.

He also advocated for broader corporate responsibility. During his tenure, Edsel pushed for better working conditions and was involved in philanthropic efforts, including the support of art institutions and museums. He helped establish the Ford Foundation in 1936, which would go on to become one of the world’s largest charitable organizations.

Struggles and legacy

Despite his accomplishments, Edsel’s career was often overshadowed by his father’s domineering presence. Henry Ford repeatedly undercut his son’s authority, reversing decisions and stifling innovation. The friction, combined with intense pressure and stress, took a toll on Edsel’s health. In 1943, at the age of 49, Edsel Ford passed away from stomach cancer.

His death was a personal and corporate tragedy. It also marked the end of a transitional era at Ford. After his passing, Henry Ford resumed the presidency temporarily before eventually passing the reins to Edsel’s son, Henry Ford II, who would modernize the company in ways that echoed Edsel’s vision.

Conclusion

Edsel Ford was more than just the son of an industrial titan. He was a visionary who brought grace and style to an industry focused on brute efficiency. Through his leadership at Lincoln, his emphasis on design, and his forward-thinking business philosophy, Edsel left an imprint on the automotive world that remains evident today. His legacy is a reminder that art and industry can, and should, coexist.

Monday, May 20, 2024

T206 baseball card set

The 1909-1911 T206 baseball card set: A comprehensive overview

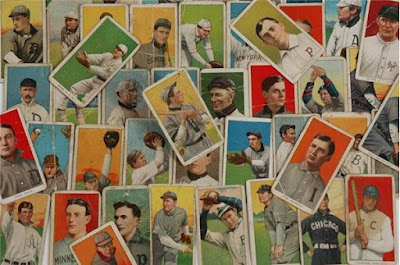

The 1909-1911 T206 baseball card set, often referred to as the "White Border" set, as well as "The Monster" due to its sheer size of 524 cards, is one of the most iconic and sought-after collections in the history of baseball card collecting. Produced by the American Tobacco Company (ATC), this set includes some of the most legendary figures in early baseball and has become a cornerstone for collectors and historians alike. This essay explores the origins, design, key cards, and enduring legacy of the beautiful, eye-appealing T206 set, truly a work of art in its own right.

Origins and production

The T206 set was produced by the American Tobacco Company (ATC) between 1909 and 1911 as part of a marketing campaign to promote its various cigarette brands, including Piedmont, Sweet Caporal, and Old Mill. Cards were inserted into cigarette packs, encouraging smokers to purchase more packs to complete their collections. This marketing strategy not only boosted cigarette sales but also left a lasting legacy in the realm of sports memorabilia.

Design and composition

The T206 set is known for its distinctive white borders, which set off the colorful lithographed portraits or action poses of players. The cards measure approximately 1.5 by 2.625 inches, a standard size for early 20th-century tobacco cards. The set features 524 known cards, depicting players from 16 major league teams and a few minor league teams.

Each card front showcases a player portrait or action pose, accompanied by the player's last name and the city of their team. The back of each card displays an advertisement for one of the ATC's cigarette brands. The combination of vivid artwork, detailed player depictions, and commercial advertising makes the T206 set a fascinating snapshot of early baseball and early 20th-century American culture.

Key cards and notable players

The T206 set is renowned for several key cards, all of whom depict Hall of Fame members, that have become legendary in the collecting world:

|

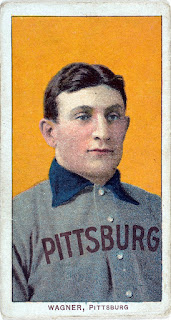

| Honus Wagner card |

Ty Cobb: The set includes four different variations of Ty Cobb, one of the greatest hitters in baseball history. The set's cards of Cobb, who played for the Detroit Tigers, are highly prized by collectors due to his on-field achievements and the striking imagery on the cards.

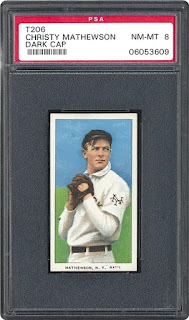

Christy Mathewson: Mathewson, a dominant pitcher of the era who threw for the New York Giants, is featured in three different poses. His cards are sought after for their historical significance and the artistry of the depictions.

Walter Johnson: Another pitching legend, Johnson, of the Washington Senators, is represented in two poses in the T206 set. His cards are valued for their rarity and for commemorating one of baseball's greatest pitchers.

Challenges of collecting

Collecting the T206 set poses several challenges. The sheer number of cards, coupled with all the variations and rarities, makes completing the set a daunting and very expensive task. Additionally, the condition of the cards can vary widely. Many T206 cards have survived the past century with significant wear and tear, making high-grade examples extremely valuable.

Legacy and impact

The T206 set's legacy extends beyond its value in the collecting world. It represents a formative period in baseball history, capturing the faces and feats of early 20th-century baseball heroes. The cards are cherished not just for their monetary worth but for their cultural, historical, and artistic significance.

|

| One of three different Christy Mathewson cards |

Conclusion

The 1909-1911 T206 baseball card set stands as a testament to the enduring allure of baseball and the rich history of American sports collecting. From the legendary Honus Wagner card to the intricate portraits of early baseball stars, the T206 set offers a window into a bygone era. For collectors and historians, it remains a cherished link to the past and a cornerstone of the hobby.

Saturday, May 18, 2024

The Men Who Built America study guide

The Men Who Built America is a multi-episode docu-drama series by the History Channel that originally aired in 2012, chronicling the lives and achievements of some of America's most influential industrialists. These men transformed the United States from a post-Civil War nation into a global economic powerhouse. This study guide provides an overview of the main figures, significant events, and key developments in manufacturing history covered in the series.

Main Industrialists

1. Cornelius Vanderbilt (1794-1877)

Industry: Railroads and Shipping

Key Achievements:

- Known as "The Commodore," Vanderbilt initially built his wealth through shipping before investing heavily in railroads.

- He established the New York Central Railroad, which became one of the most important transportation networks in the United States.

- Vanderbilt's aggressive business tactics and strategic acquisitions helped consolidate the rail industry, reducing costs and improving efficiency.

Industry: Oil

Key Achievements:

- Founded Standard Oil in 1870, which quickly grew to dominate the oil industry through horizontal integration.

- Implemented innovative business practices, including the use of pipelines to transport oil, reducing reliance on railroads.

- His company controlled 90% of the oil refineries and pipelines in the United States at its peak, making Rockefeller one of the wealthiest individuals in history.

3. Andrew Carnegie (1835-1919)

Industry: Steel

Key Achievements:

- Immigrated from Scotland and started working in a cotton factory before moving into the railroad industry.

- Founded Carnegie Steel Company, which revolutionized steel production with the adoption of the Bessemer process.

- His focus on efficiency and vertical integration helped make steel more affordable and accessible, fueling infrastructure growth.

4. J.P. Morgan (1837-1913)

Industry: Banking and Finance

Key Achievements:

- A powerful banker who financed the reorganization of railroads, insurance companies, and banks.

- Played a crucial role in the formation of General Electric and U.S. Steel Corporation.

- His influence extended beyond finance, impacting various sectors through strategic investments and mergers.

5. Henry Ford (1863-1947)

Industry: Automotive

Key Achievements:

- Founded the Ford Motor Company in 1903.

- Revolutionized manufacturing with the introduction of the moving assembly line, significantly reducing the time and cost of producing automobiles.

- His Model T became the first affordable car for the average American, democratizing automobile ownership and transforming transportation.

Key Events

1. The Railroad Revolution

- The expansion of the railroad network was crucial to America's industrial growth.

- Facilitated the movement of goods and people across vast distances, linking previously isolated regions.

- Enabled the rise of other industries, such as steel and oil, by providing efficient transportation.

- Standard Oil's dominance exemplified the power of monopolies and the effectiveness of horizontal integration.

- The company faced significant backlash and legal challenges, leading to the landmark antitrust case resulting in its breakup in 1911.

- Highlighted the need for regulations to curb monopolistic practices and ensure fair competition.

3. Steel and Infrastructure

- Steel's affordability and strength made it the material of choice for building infrastructure, including railroads, bridges, and skyscrapers.

- The growth of the steel industry under Andrew Carnegie's leadership was pivotal to America's modernization.

- Steel production techniques and innovations set the stage for large-scale construction projects.

- J.P. Morgan's role in consolidating industries and stabilizing the economy was crucial during periods of financial instability.

- His intervention during the Panic of 1907 helped prevent a banking collapse, demonstrating the power of private finance in stabilizing the economy.

- Morgan's influence on corporate America underscored the importance of financial networks in industrial growth.

- Henry Ford's development of the assembly line transformed manufacturing practices across industries.

- The widespread adoption of automobiles changed the American landscape, leading to the construction of roads and highways.

- Ford's innovations contributed to the growth of the middle class by providing affordable transportation and high-paying jobs.

Manufacturing History and Innovations

1. The Bessemer Process

- Invented by Henry Bessemer, this process allowed for the mass production of steel by removing impurities from iron using a blast of air.

- Andrew Carnegie's adoption of this process made steel production faster and more cost-effective, facilitating large-scale infrastructure projects.

- Introduced by Henry Ford, the moving assembly line drastically reduced the time required to produce a single automobile from 12 hours to just 90 minutes.

- This innovation not only revolutionized the automotive industry but also influenced manufacturing processes in various sectors, leading to greater efficiency and lower costs.

3. Vertical and Horizontal Integration

- Vertical integration involves controlling every aspect of production, from raw materials to final products, as practiced by Andrew Carnegie in the steel industry.

- Horizontal integration focuses on consolidating multiple firms within the same industry to monopolize the market, exemplified by John D. Rockefeller's Standard Oil.

- J.P. Morgan's strategies in reorganizing and consolidating industries demonstrated the power of financial engineering in stabilizing and growing businesses.

- His approach involved the merging of competing firms to create monopolies or oligopolies, ensuring stability and profitability.

- Rockefeller's investments in refining and transportation infrastructure, such as pipelines, reduced costs and increased efficiency in the oil industry.

- These innovations played a significant role in establishing oil as a dominant energy source and Standard Oil as a major industrial power.

The Men Who Built America provides a compelling narrative of the industrial titans who shaped modern America. Their innovations in transportation, manufacturing, finance, and corporate strategy not only revolutionized their respective industries but also laid the groundwork for the United States' emergence as a global economic leader. Understanding their contributions and the historical context of their achievements offers valuable insights into the evolution of industrialization and its lasting impact on the world.

Lincoln Continental Mark V

Introduction

The Lincoln Continental Mark V, manufactured by the Ford Motor Company from 1977 to 1979, is a hallmark of American luxury automobiles from the late 1970s. Known for its distinctive size, elegant design, and powerful engines, the Mark V is a quintessential example of the era's preference for opulence and comfort in automotive design. This essay explores the Mark V's power plants, production specifics, trim levels, stylistic features, and sales performance.

Power plants

The Lincoln Continental Mark V was equipped with two types of V-8 engines during its production run:

400 cu. in. (6.6-liter) Cleveland V-8:

This engine was standard in most states, delivering adequate power for the car's substantial size. It featured a 2-barrel carburetor and was noted for its smoother operation in urban settings. The 400 was the standard engine in all states for 1979 due to growing emissions regulations at the federal level.

460 cu. in. (7.5-liter) Lima V-8:

Optional or standard, depending on the state, due to emissions regulations. Not an option in any state for 1979. Known for its higher torque and power, the 460 V-8 was favored for its performance, particularly while under load or in highway cruising.

These engines represented Ford's response to consumer demands for performance without sacrificing the luxurious feel expected from a high-end model like the Mark V.

Production and manufacturing

The Mark V was produced over three model years with significant production numbers:

1977: Introduction year, catching the market with its fresh design.

1978: Peak production year, reflecting the model's popularity.

1979: Last production year, with numbers slightly tapering off as new models were on the horizon.

Ford manufactured the Lincoln Continental Mark V at its Wixom Assembly Plant in Michigan, a facility known for producing luxury models. This plant's association with high-end vehicle manufacturing ensured that the Mark V met quality standards expected by luxury car buyers.

Trim levels and stylistic features

The Mark V came in various trim levels, each offering a different blend of luxury and style:

- Base model: Featured standard luxury touches expected from Lincoln, including plush seating and high-end audio systems.

- Designer editions: Collaborations with famous fashion designers like Bill Blass, Cartier, Givenchy, and Pucci, each offering unique color schemes, interior fabrics, and exterior markings.

- Collector's Series: A special trim level to mark the end of the Mark V production, featuring special paint colors, a padded vinyl roof, and luxurious interior appointments.

Sales and market performance

The Lincoln Continental Mark V was a commercial success.

Sales: Consistently strong sales figures throughout its production run, with the peak in 1978. The luxury market's demand for big, stylish cars played a significant role in its sales performance.

Market position: The model reinforced Lincoln’s position in the luxury car market, competing directly with other high-end models from Cadillac and Chrysler.

Conclusion

The Lincoln Continental Mark V stands out as a symbol of late 70s luxury, combining powerful V-8 engines with a design that exuded elegance and a high level of craftsmanship. Its success in the market was not just due to its performance and style but also Ford's strategic manufacturing and marketing approaches. Today, the Mark V is celebrated among classic car enthusiasts for its iconic design and the era of automotive history it represents.

Wednesday, May 8, 2024

B-17 Flying Fortress

Introduction

The Boeing B-17 Flying Fortress is one of the most iconic aircraft of World War II, embodying the American strategic bombing campaign with its robustness, advanced technology, and heavy bomb load capabilities. Its service during the war was pivotal in the Allied victory in Europe, targeting strategic enemy infrastructure. This essay explores the specifications, production variants, combat losses, achievements during the war, and modern restoration efforts of the B-17. It also highlights the famous B-17, the Memphis Belle, celebrated for completing 25 missions without losing a crew member.

Specs

The B-17, initially produced by Boeing, featured a wingspan of 103 feet and a length of 74 feet. Powered by four Wright R-1820 Cyclone engines, each engine produced 1,200 horsepower, enabling the B-17 to have a maximum speed of about 287 mph and a service ceiling of 35,600 feet. These engines were manufactured by Wright Aeronautical, a key player in mid-20th-century aircraft engine production.

Variants and production

Throughout its production life, from 1936 to 1945, the B-17 saw several variants, each improving on its predecessor. The B-17E introduced a larger tail fin and a gunner's position at the tail to address defense vulnerabilities. The B-17F had upgraded engines and a revised, more heavily armed nose. The B-17G, the most produced variant, featured a chin turret for better frontal defense, making it one of the most definitive models.

Over 12,700 B-17s were built by Boeing, along with significant contributions from Douglas and Lockheed (under the Vega brand). This mass production was a monumental feat of wartime industrial effort, emblematic of the broader American wartime production capability.

Combat service and losses

The B-17s were primarily employed in the daylight strategic bombing of Nazi Germany, which was a contentious strategy due to the high risk of aircraft losses. They targeted factories, oil refineries, and transport infrastructure, contributing significantly to the weakening of Nazi war capabilities. The United States Army Air Forces (USAAF) lost approximately 4,750 B-17s in combat missions during the war, illustrating the high cost of the air war in Europe.

Accomplishments in World War II

The B-17 achieved numerous accomplishments during World War II. One of the most significant was its role in the combined bomber offensive, culminating in critical missions like the raid on Schweinfurt and Regensburg, which targeted ball bearing plants and aircraft factories, respectively. These missions, though costly in terms of aircraft and crew losses, were crucial in depleting the German war machine.

Modern restoration and flight worthiness

Today, numerous B-17s are preserved and restored by various organizations and museums. These aircraft are often made airworthy and flown at air shows to educate the public about World War II and aviation history. Organizations like the Collings Foundation and the Commemorative Air Force maintain and operate these planes, ensuring that they continue to fly, serving as a living history lesson.

The Memphis Belle

The most famous B-17, the Memphis Belle, gained legendary status by becoming the first U.S. Army Air Force bomber to complete 25 missions over Europe and return to the U.S. The aircraft and its crew became symbols of the durability and effectiveness of the strategic bombing campaign. After the war, the Memphis Belle was restored and is now displayed at the National Museum of the United States Air Force in Dayton, Ohio.

Conclusion

The Boeing B-17 Flying Fortress remains a towering figure in military aviation history. Its contribution to the Allied victory in World War II through strategic bombing campaigns, despite substantial losses, is a testament to its design and capabilities. The ongoing restoration efforts keep the legacy of the B-17 alive, allowing future generations to witness this flying fortress in the skies.

Sunday, March 17, 2019

Manufacturing and the trades in schools

Recently, I published a post on here entitled, "I was a slacker in high school," in which I discussed the regrets I still have all these years later for not taking high school more seriously. That post generated quite a bit of buzz, fielding over 500 hits in less than a day and a couple of reader comments below the post. I'm really grateful for all the interest and positive feedback surrounding that post, and I truly hope it can serve as a teachable moment.

Today, I want to talk about another important factor that affected my time in high school in, looking back on it, a negative way, as well, and how younger generations of high school students and graduates are now benefiting from a renaissance in programming, resources, and real conversations. I'm talking about the resurgence in manufacturing and the trades in schools.

I graduated high school in 2001. While I was in high school in the late 1990s, manufacturing in the United States was undergoing a serious exodus. Perhaps the hardest hit areas were in the Midwest, where manufacturing was a way of life, providing many families with a stable, comfortable, middle-class lifestyle. Many of the men in my family, along with many of our family friends, were skilled machinists. And many of them lost their jobs in the late 90s, including my father, an uncle, and even my mother, who did assembly work. Many plants during this time closed up shop and moved down to Mexico, where labor and other resources were much cheaper.

At the time, the message to those of us in high school was, "Avoid manufacturing. It's dead in this country. There's no future in it. Go to college." The four-year university was all the talk. That was the path we were all encouraged - even outright steered toward - to pursue. Many students from my generation, including myself, were the first ones in our families to go to university. Pursuing a university education, we were told, would lead to a great, comfortable living, and one that's clean - away from the oily, dirty, dim-lit environment often associated with machining and factory work back then, however real or merely perceived.

Simultaneously, the other trades, along with technical colleges and vocational schools, were largely downplayed as post-high school options, as well. These jobs and paths just weren't really talked about much, it seemed, and when they were, they were often cast in the same light as the then-disappearing jobs in the manufacturing realm - grimy, labor-intensive, whatever the opposite of the pristine, well-lit, promising, and even futuristic jobs being churned out by the white-collar world. The university, we were told by our parents, teachers, guidance counselors, the media, and broader society, was the way of the future. Many schools were scaling back or outright eliminating shop and tech ed programs, or they were on their way to doing so in subsequent years.

There's just one problem with this widely-held blind faith in the university system - unless we want to go back to kerosene lamps, outhouses, primitive buildings and living spaces, making our own tools and utensils, and horse and carriage for transportation, we will always need electricians, plumbers, carpenters, painters, drywallers, welders, mechanics, machinists, assembly workers, automotive workers, you name it.

Flash forward to today. In more recent years, especially the present day, the tide has shifted back to fully embracing trades education. We as a society are back again to encouraging technical colleges and vocational schools as viable post-high school options. We're reviving old and establishing new partnerships to funnel students and graduates into skilled labor employment and apprenticeships. And we're simply having real conversations of substance. And, in a somewhat ironic twist, it's these types of jobs and career tracks that are the ones offering the comfortable, promising living these days. Furthermore, manufacturing facilities have come a long ways in cleanliness and lighting levels to match!

See, we've managed to ignore, downplay, or steer away from these lines of work for so long, while simultaneously over-flooding the market with bachelor's degree holders, that there are huge labor shortages - and hence big-time demand for young adults showing an interest and aptitude for them.

Now, I don't regret my university education and subsequent graduate-level studies. Through this education, I've discovered and enjoyed a lot of work meaningful and satisfying to me over the years, including various stints in entrepreneurship. I've also established and have benefited from quite a few professional and networking relationships, many of which have become close, personal friendships. But while I have no regrets on my university education, I also wish that these opportunities were discussed and presented to us in a more positive - literally, a more honest - light back then. Big opportunities that you now have if you're interested.

Want the best of both worlds? I typically advise students these days to take a serious look at a technical college or vocational school education. Learn a provable hard skill or trade first, something that you're really going to enjoy. Enter the workforce with those skills and gain some practical on-the-job experience for a while. And then consider going for the bachelor's and perhaps even beyond, if that's something you'd like to do. Maybe get a bachelor's in a business/management/leadership program. Now, you have two good things going for you - first, you have that concrete, verifiable skill set. And you'll also have that bigger-picture education that can help you set the stage for a promotion into management or even off on your own as a business owner yourself some day.